With the rapid development of China’s manufacturing industry, aluminum metal is increasingly used in various industries. Magnetic polishing, as a cutting-edge aluminum surface treatment process, is of great significance for improving aluminum surface quality and optimizing product characteristics. This paper will systematically discuss the application and quality of magnetic polishing technology in aluminum processing.effect of magnetic polishing machine.

First, magnetic polishing technology introduction

Magnetic polishing is a process of surface polishing using magnetic abrasives and magnetic fields. Compared with traditional polishing methods, magnetic polishing has the characteristics of high polishing efficiency, good effect and low cost.

Second, the use of magnetic polishing in aluminum processing

1, improve the surface quality of aluminum

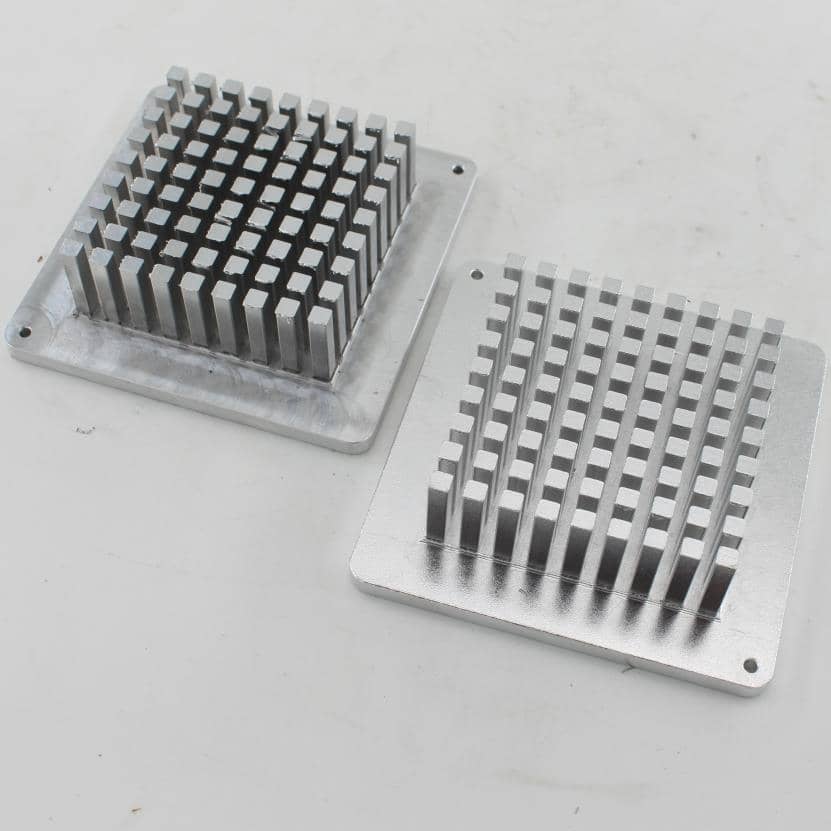

Magnetic polishing technology can effectively improve the surface quality of aluminum parts, so that the surface of aluminum parts is highly smooth. In the production of aluminum parts, magnetic polishing can significantly improve the surface of the aluminum parts of the microscopic unevenness, improve the wear resistance of aluminum parts, corrosion resistance and aesthetics.

2, improve the characteristics of aluminum parts

In the magnetic polishing process, magnetic abrasives are used to solve the microscopic defects on the aluminum surface, making the aluminum surface cleaner. This helps to improve the process properties of aluminum parts, such as tensile and compressive strength. In addition, magnetic polishing removes stress from the aluminum surface, reducing the risk of aluminum rupture during use.

3, reduce the production cost of aluminum parts

Magnetic polishing technology utilizes magnetic abrasives and magnetic field force for polishing, eliminating the need for large quantities of polishing fluids and cloths. This helps to reduce material and labor costs in the aluminum processing process and improve work efficiency.

Third, magnetic polishing effect analysis-effect of magnetic polishing machine

1, better polishing effect

Through the magnetic polishing and other polishing methods (such as traditional polishing, cutting, etc.) comparison experiments, it is easy to see that magnetic polishing in improving the surface quality of aluminum has obvious advantages. Magnetic polishing aluminum surface gloss and flatness is better than other polishing methods.

2, process indicators on the effect of polishing

Magnetic polishing effect by polishing speed, magnetic abrasive particle size, magnetic field strength and other process indicators. In actual production, these parameters can be adjusted to optimize the polishing effect. For example, moderately increase the polishing speed and magnetic field strength can improve the polishing efficiency and polishing effect; Select the appropriate magnetic abrasive particle size, can make the aluminum surface in the polishing process by uniform cutting force, to prevent scratches and ripples.

3, the practical application of magnetic polishing

In practical application, magnetic polishing technology in aluminum parts manufacturing has achieved good results. Many aluminum manufacturing enterprises through the introduction of magnetic polishing equipment and technology to improve product quality and market competitiveness. At the same time, magnetic polishing technology is also widely used in aerospace engineering, automotive industry, electronic products and other fields.

The application of magnetic polishing technology in aluminum parts processing has significant advantages. It can improve the surface quality of aluminum parts, optimize product characteristics and reduce costs. Based on the improvement of the magnetic polishing process index, the polishing effect can be further improved. With the continuous development and improvement of magnetic polishing technology, I firmly believe that it will play a greater role in the aluminum processing industry in the future.

يجب أنت تكون مسجل الدخول لتضيف تعليقاً.