In the production of metal extruded parts, surface quality is one of the important standards for measuring products. In order to meet this standard, many enterprises have started to use magnetic polishing machines to improve production efficiency and product quality. This article will introduce the application background, process flow, advantage analysis, and application cases of magnetic polishing machines in the production of metal extruded parts.The Application of Magnetic Polishing Machine in the Production of Metal Extrusion Parts.

process flow

The process flow of magnetic polishing machine in the production of metal extruded parts includes the following steps:

Cleaning: Firstly, place the metal extrusion into a cleaning agent to remove surface dirt and oxide layer.

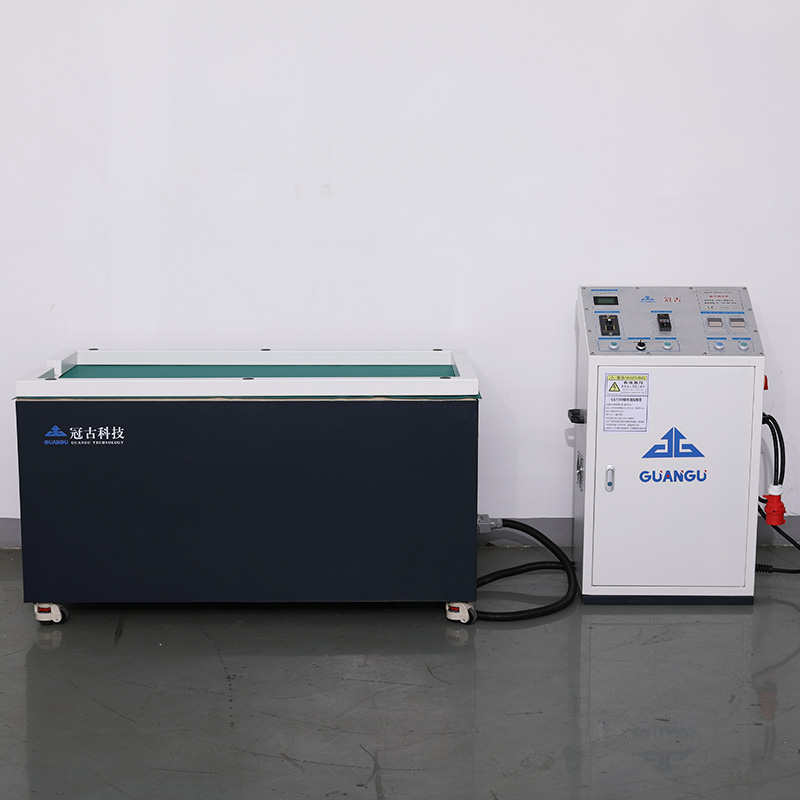

Polishing: Place the cleaned metal parts into the polishing groove of a magnetic polishing machine, and use a high-speed rotating magnetic grinding stone to polish the metal surface to remove roughness and scratches.

Polishing: Place the polished metal part into a polishing groove, and use the action of a magnetic abrasive stone and polishing fluid to make the metal surface smoother and brighter.

Cleaning and drying: Finally, clean and dry the polished metal parts to remove polishing solution and moisture from the surface.

Advantage analysis

Compared to other processing methods, magnetic polishing machines have the following advantages:

Efficiency: The magnetic polishing machine uses high-speed rotating magnetic grinding stones, which can quickly remove roughness and scratches on the metal surface, effectively improving production efficiency.

Quality: Due to the physical grinding method used by the magnetic polishing machine, it will not cause damage to the metal surface, thereby improving product quality.

Cost: Magnetic polishing machines have lower energy consumption and do not require a large number of workers to operate, thus reducing production costs.

Application Cases

When a certain automobile manufacturing enterprise uses traditional processing methods to produce engine cylinder blocks, the surface quality cannot meet the requirements, resulting in unstable engine performance. To solve this problem, the company introduced a magnetic polishing machine to polish the surface of the cylinder block. After polishing, the surface smoothness of the cylinder block has been significantly improved, and the engine performance has also been significantly improved. This successful case fully demonstrates the promotion value and significance of magnetic polishing machines in the production of metal extruded parts.

summary-The Application of Magnetic Polishing Machine

As an advanced surface treatment equipment, magnetic polishing machines are playing an increasingly important role in the production of metal extruded parts. It has been successfully applied in fields such as automobiles, aerospace, electronics, etc., with its advantages of efficiency, high quality, and low cost, improving production efficiency and product quality for enterprises. With the continuous progress of technology and the increase of market demand, the application prospects and potential market space of magnetic polishing machines will be even broader.

However, in order to better leverage the advantages of magnetic polishing machines, it is necessary to strengthen equipment development and process optimization, improve the stability and reliability of the equipment, and meet the production needs of metal extrusion parts in different fields and materials. At the same time, strengthening industry exchanges and talent cultivation, improving people’s understanding and application level of magnetic polishing machines, is also an important way to promote the widespread application of magnetic polishing machines.

يجب أنت تكون مسجل الدخول لتضيف تعليقاً.